Hot melt mylar manufacturer

Time:

2025-09-28 15:28

Source:

Quick Details

| Place of Origin: | Guangdong, China | Brand Name: | Dilo |

| Model Number: | DN-TIW-PET-1 | Type: | Insulation Film |

| Material: | PET | Application: | LOW VOLTAGE |

| Rated Voltage: | 1000 | Tensile Strength: | 5kgf/mm2 |

| Color: | Customized | Width: | Cutting |

| Thickness: | Customer Demands | Adhesive: | Hot Melt Adhesive Coated |

| Length: | 1k-12km | Usage: | wire wrapping |

| Certification: | UL | RoHS: | Yes |

| Advantage: | Thin and colored | Sample: | Sample Avaliable |

Supply Ability

Supply Ability: 400000 Roll/Rolls per Month

Packaging & Delivery

Packaging Details: Packed in cardboard box with fumigation free pallete or non-wood pallete

Port: HongKong, Shenzhen, Humen, Shanghai

Lead Time:

| Quantity(Meters) | 1 - 100 | 101 - 1000 | >1000 |

| Est. Time(days) | 3 | 7 | To be negotiated |

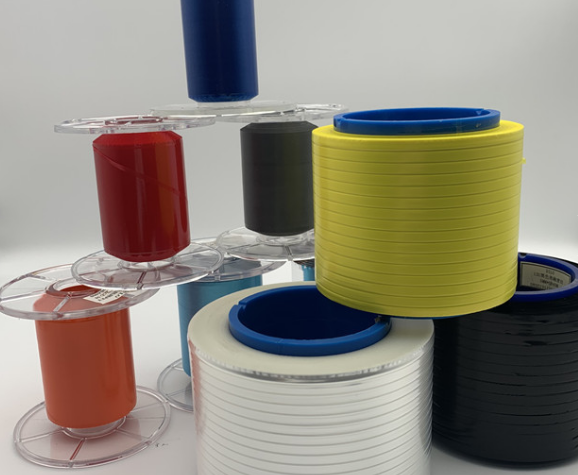

Hot melt adhesive coated mylar wrap film

Hot melt mylar is mylar film coated with a layer of hot melt glue. It is widly used in wire wrapping, especially high frequency wires like earphone wire, and triple insulated wires.

Triple insulated wire is a high-end wire product that can be used in small transformers and other products. It requires insulated and temperature resistance performances.

Our mylar product is specially made for high frequency wire and triple insulated wires. It's color, thickness and width are customized, and length about 10km per roll can be customized. hot melt adhesive can bond the wires tightly when the wires passes through the heat oven.

This product is RoHS free product and has passed UL certificate.

| Thickness | μm | 10 | 20 |

Total thickness | μm1 | 14±3 | 20±3 |

Elongation | % | 30 | 30 |

Tensile strength | kgf/mm2 | 5 | 5 |

Temperature | ℃ | 90-120 | 90-120 |

Heat seal strength | kgf/15mm | 0.3 | 0.3 |

My Wechat:TiNO-Tina or 13694945590

WhatsApp:+86 13694945590

Email:world@dilo-china.com

Hot melt mylar has become an increasingly popular material in various industries due to its excellent durability, versatility, and strong bonding capabilities. As modern manufacturing continues to evolve, hot melt mylar provides a reliable solution for businesses seeking high-quality materials that combine strength, performance, and ease of use. By incorporating hot melt mylar into production processes, companies can improve product quality, reduce costs, and achieve greater efficiency.

One of the most significant advantages of hot melt mylar is its superior bonding ability. Unlike traditional adhesives, hot melt mylar offers consistent adhesion across multiple surfaces, including metals, plastics, textiles, and composite materials. This strong bonding capability ensures that products remain secure and reliable, even under demanding conditions. Many manufacturers prefer hot melt mylar for this reason, as it minimizes the risk of product failure while maximizing performance.

Another key benefit of hot melt mylar is its resistance to temperature changes. Products made with hot melt mylar can maintain stability in both high-heat and low-temperature environments. This thermal resistance makes it a perfect choice for applications such as automotive components, electronics, and industrial machinery, where exposure to temperature fluctuations is common. By using hot melt mylar, manufacturers can ensure that their products perform consistently, regardless of environmental challenges.

Hot melt mylar is also valued for its flexibility and versatility. It can be adapted to a wide range of production needs, from packaging and lamination to electrical insulation and protective layering. In packaging industries, hot melt mylar provides a strong yet lightweight material that improves product safety during transportation and storage. In the electronics sector, it serves as an effective insulating layer that enhances durability while preventing damage from heat or electrical interference.

Durability is another defining characteristic of hot melt mylar. Unlike some traditional materials, hot melt mylar resists tearing, wear, and chemical exposure. This makes it especially suitable for long-term applications in industries such as aerospace, construction, and renewable energy. Products reinforced with hot melt mylar not only last longer but also require less maintenance, reducing overall costs for manufacturers and end users alike.

From a production perspective, hot melt mylar offers time-saving benefits. Its application process is faster compared to conventional bonding methods, allowing for increased efficiency on manufacturing lines. Hot melt mylar adheres quickly and does not require lengthy drying or curing times, which means products can move through assembly stages more efficiently. This speed helps companies meet higher production demands while maintaining consistent quality standards.

Additionally, hot melt mylar supports sustainability efforts. Many companies are shifting toward eco-friendly solutions, and hot melt mylar contributes to this goal. Its efficient use reduces waste, and its compatibility with various recycling processes makes it a responsible choice for businesses aiming to reduce environmental impact. By selecting hot melt mylar, manufacturers not only benefit from superior material performance but also demonstrate a commitment to greener practices.

Related news

Tino Electronic Material: Your professional Aluminum Mylar Spool exporter, delivering precision-engineered spools for superior material protection and handling efficiency worldwide

Tino Electronic Material: Leading Hot Melt Mylar manufacturer, producing premium thermal-bonding polyester films for advanced electronic and industrial applications globally

Tino Electronic Material Ships Aluminum Foil and Cotton Paper to Vietnam

Aluminum Foil and Cotton Paper

Step-by-Step Guide to Using Adhesive Acetate Fabric Tape Safely

Step-by-Step Guide to Using Adhesive Acetate Fabric Tape Safely Overview of Adhesive Acetate Fabric Tape Adhesive acetate fabric tape is a versatile tool in various industries, including crafting, fashion design, and electrical work. Its unique properties provide both adhesion and durability, making it an essential component in many projects. This guide will explore the **benefits**, **applica