What are the material ingredients of Low price Non woven fabric tape

Time:

2023-10-26 15:14

Source:

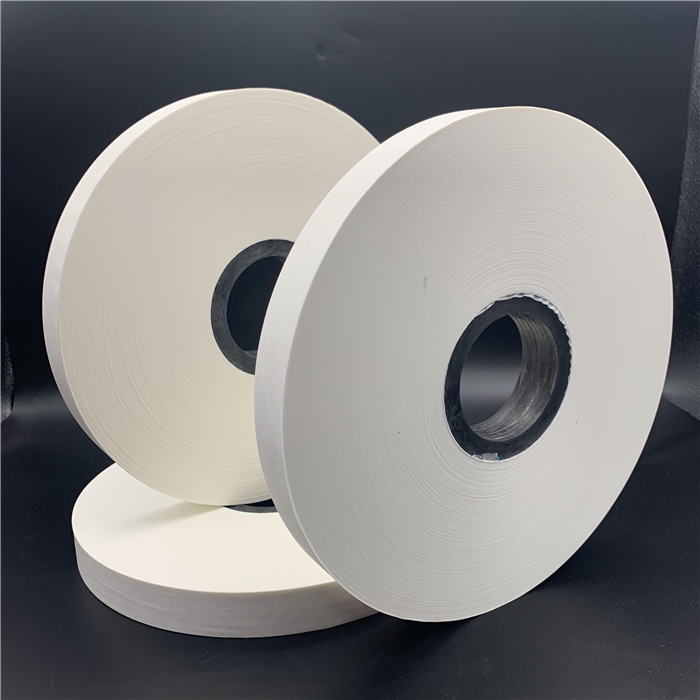

What are the material ingredients of Low price Non woven fabric tape? Low price Non woven fabric tape is different from general textiles in terms of material composition. In order to ensure the excellent breathability and flexibility of non-woven fabrics, and improve the stretchability and quality of non-woven fabrics, non-woven fabrics are processed to produce material composition. There is a big difference between the above and general textiles!

Low price Non woven fabric tape mostly uses polypropylene (pp material) pellets as raw materials, and is produced by a continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing.

The three major fibers used in the production of Low price Non woven fabric tape are polypropylene (62% of the total), polyester (24% of the total) and viscose (8% of the total). From 1970 to 1985, viscose fiber was used the most in the production of non-woven fabrics. However, in the past five years, polypropylene fiber and polyester fiber have become dominant in the fields of hygienic absorbent materials and medical textiles.

Low price Non woven fabric tape production fibers are mainly polypropylene (PP) and polyester (PET). In addition, there are nylon (PA), viscose fiber, acrylic fiber, polyethylene fiber (HDPE), and chlorine fiber (PVC). According to application requirements, non-woven fabrics are divided into two categories: disposable application type and durable type.

To sum up, the low price non woven fabric tape is made of many material components, which are mainly distinguished by what purpose it is used for. Here I will briefly explain, the materials are polyester, polypropylene, aramid, acrylic, nylon, composite, ES, 6080, vinylon, spandex, etc., I said they are all fibers. The selling price of Non woven fabric tape produced with different materials and different processes is very different.

Related news

Tino Electronic Material Co., Ltd. Successfully Ships Mylar Aluminum Foil Rolls to South Korea

Mylar aluminum foil roll, aluminum foil Mylar supplier, cable shielding materials, PET aluminum foil Korea import, Tino Electronic Material Co., Ltd., cable material manufacturer China, Mylar foil for communication cables, aluminum Mylar tape exporter, shielding foil for electronics, Guangdong electronic materials supplier

Tino Electronic Material Co., Ltd. Announces Successful Shipment of Precision Copper Strip to France

copper strip supplier, copper strip 0.075mm, conductive copper tape material, copper foil for cables

Free High-Quality Non-Woven Fabric Delivered to Indian Customers

Non-woven fabric,Wire harness wrapping material: Used for bundling and wrapping cable harnesses to achieve neat wiring and auxiliary insulation.

Double-Sided Conductive Copper Foil Tape,EMI/RFI shielding/PCB and FPC grounding/Cable and connector wrapping/Battery packs and electronic assemblies/Anti-interference components in consumer electronics

aluminum foil tape, PI tape, polyimide tape, cable wrapping materials, electronic insulation materials, conductive shielding tape, electrical wire and cable materials, Tino Electronic Material Co., Ltd., industrial adhesive tapes supplier, Georgia electronics market, high-temperature insulation tape

Understanding PP Foam Tape: A Versatile Solution for Electrical Insulation

PP foam tape, often recognized for its unique characteristics, serves as an essential component in various electrical insulation applications. This type of tape is made from polypropylenes, which are known for their lightweight, durability, and resistance to moisture and chemicals. Its foam structure allows for excellent cushioning and sealing properties, making it an ideal choice for a range of p